The Vibro Air-Operated Transporter is the right choice for linear scrap removal from punch presses, lathes and other automatic multi-functional machine tools. The principle behind the Vibro Air-Operated Transporter design is its pneumatic cylinder. With a slow acceleration in the forward stroke, material will be transported forward. During the rapid return stroke, material will remain stationary, thus ensuring constant movement in one direction only.

Because of its compact design, the Vibro Air-Operated Transporter may be installed in cramped, congested areas. Unlike other transporters, the Vibro Air-Operated Transporter does not need to be located in close proximity to the tool. A scrap removal tray can be provided to fit in close quarters at the point of scrap ejection.

The Vibro Air-Operated Transporter eliminates scrap removal downtime usually associated with ordinary conveying systems. And, because it is adaptable for multi-tray installation, the Vibro Air-Operated Transporter can replace more than one conventional belt conveyor. Its simple and robust design, available in a range of materials, make the Vibro Air-Operated Transporter a reliable, efficient and cost effective choice.

The Vibro Air-Operated Transporter is easily adaptable to meet your needs. A variety of stainless steel trays can be mounted on the unit. Customers often maximize their productivity by attaching 2 or more parallel trays. The length of the tray presents no problem if you use bearing supports. Vibro industries can also provide custom bearing supports.

To increase or decrease product flow, simply turn the adjustable screw to control the movement on the tray. To control movement speed, adjust the air pressure to between 35 and 80 lbs PSI. As an option, Vibro offers a safety control to automatically shut down your system if air service is ever interrupted (your machine will automatically stop in 6 seconds).

Key Features Include:

• Two Year Warranty

• No Mechanical Springs

• Low Air Consumption

• Variable Speed (12-40 ft./min.)

• Available from Stock

• 100% American Made

• Bearing extractor kit – To include bearing extractor, rod, and 4 bearings (for model 320, 450, and 850)

Optional Features Include:

• A Cover Guard for harsh environments

• Quick Clamps for fast tray removal

• Adjustable Bearing Support for trays

• A Motion Sensor that automatically shuts down machinery if air supply is ever interrupted

Vibro Model 250 & 320 Technical Specifications:

| Model 250 | Model 320 | |

|---|---|---|

| Air Pressure Range | 35 – 80 psi | 35 – 80 psi |

| Air Consumption | 0.7 cfm @ 35 psi |

0.6 cfm @ 35 psi |

| Feed Rate (feet per minute) | 12 – 35 (3 – 10 m) |

15 – 40 (4.5 – 12 m) |

| Sound Level (db-A) | 60 | 65 |

| Maximum Load | 25 lbs. (11 kg) |

60 lbs. (27 kg) |

| Maximum Weight of Tray | 5 lbs. (1.3 kg) |

25 lbs. (11 kg) |

| Transporter Weight | 2 lbs. (0.9 kg) |

13 lbs. (6 kg) |

Vibro Model 450 & 850 Technical Specifications:

| Model 450 | Model 850 | |

|---|---|---|

| Air Pressure Range | 35 – 80 psi | 35 – 60 psi |

| Air Consumption | 0.4 cfm @ 35 psi |

3.4 cfm @ 40 psi |

| Feed Rate (feet per minute) | 15 – 40 (4.5 – 12 m) |

15 – 40 (4.5 – 12 m) |

| Sound Level (db-A) | 64 | 68 |

| Maximum Load | 125 lbs. (56 kg) |

500+ lbs. (226 kg) |

| Maximum Weight of Tray | 60 lbs. (27 kg) |

100 lbs. (45 kg) |

| Transporter Weight | 30 lbs. (13 kg) |

46.5 lbs. (21 kg) |

The Vibro Model 850 Air-Operated Transporter

The Vibro Model 450 Air-Operated Transporter

Model 320 Air Transporter Conveying System by Vibro Industries

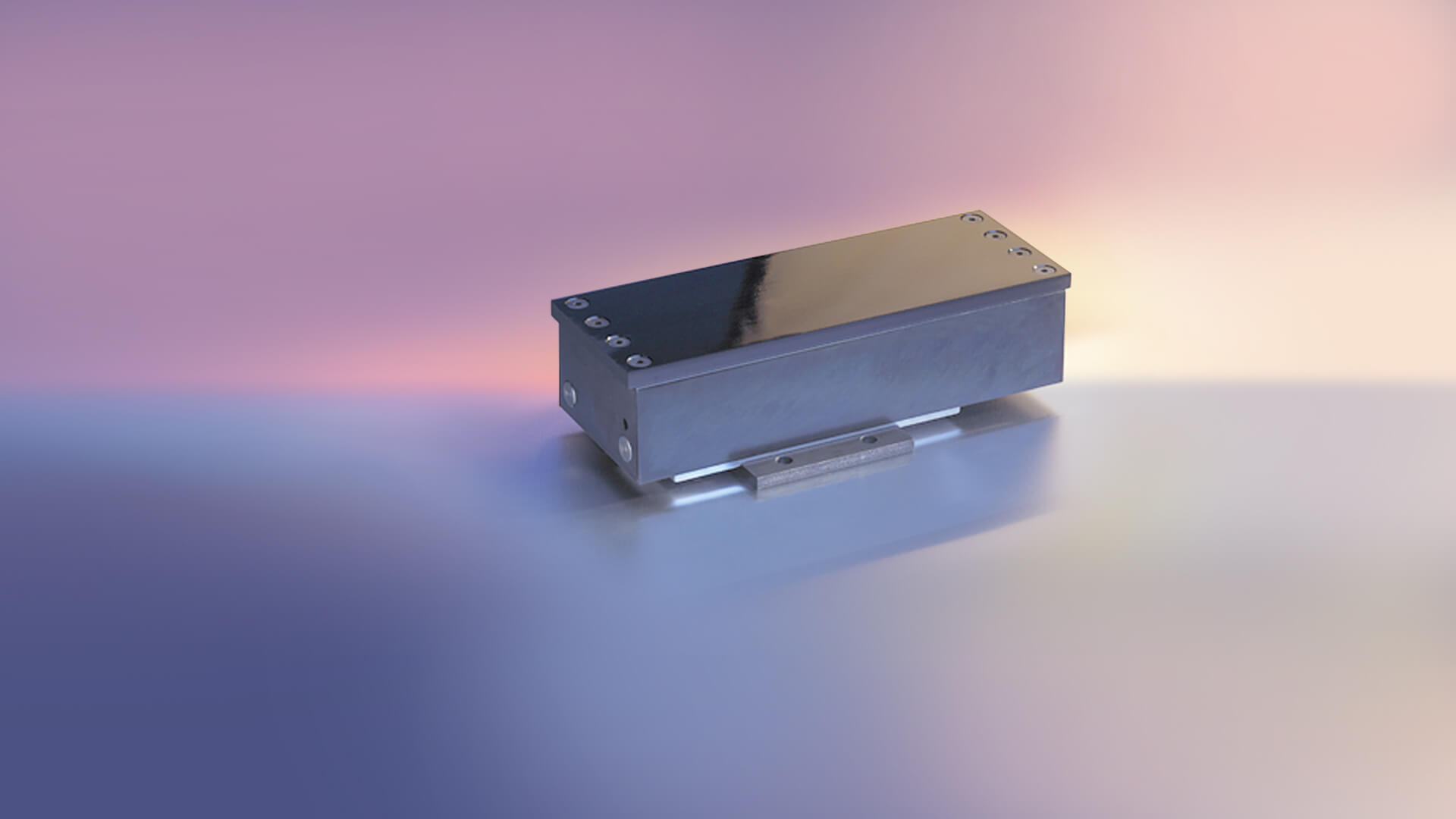

The Vibro Model 250 Air Transporter

The Vibro Transporter Motion Sensor